Welcome to our blog post on the intricacies of manual transmission rebuilds. If you’re experiencing issues with your transmission and are curious about the process of rebuilding it, you’re in the right place.

This comprehensive guide will walk you through the essential steps, from identifying common signs of transmission problems, to disassembling and inspecting the components, to replacing worn or damaged parts. We’ll also cover proper assembly techniques and share tips on testing and fine-tuning the rebuilt manual transmission. So let’s dive in and gain a better understanding of how to tackle this essential automotive task.

Understanding The Basics Of Manual Transmission Rebuild

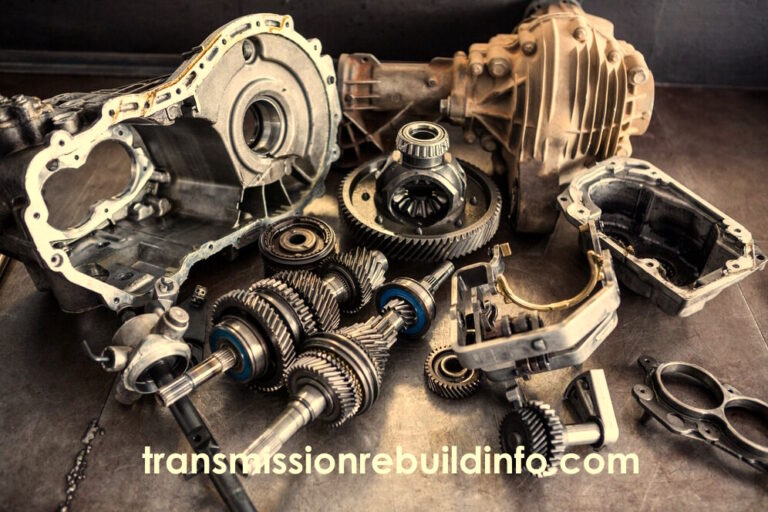

Understanding the basics of manual transmission rebuild is essential for any mechanic or car enthusiast. A manual transmission rebuild involves disassembling, inspecting, cleaning, replacing worn or damaged parts, and properly assembling the transmission to ensure its optimal performance. This blog post will provide a step-by-step guide on how to rebuild a manual transmission, highlighting the importance of each process and providing useful tips and techniques.

Before embarking on a manual transmission rebuild, it is crucial to identify common signs of transmission problems. These may include grinding or popping noises during gear shifts, difficulty in shifting gears, slipping gears, or leaking fluid. By recognizing these signs, you can address the underlying issues and prevent further damage to your transmission.

The first step in the manual transmission rebuild process is disassembling the transmission. This involves removing the transmission from the vehicle, draining the fluid, and carefully disassembling the various components. It is important to handle each part with care and keep track of their positions to ensure proper reassembly later.

- Use a drain pan to collect the transmission fluid and dispose of it appropriately.

- Disconnect the transmission from the engine and remove any remaining connections.

- Support the transmission with a jack before removing the mounting bolts.

After disassembling, it is crucial to inspect and clean each transmission component thoroughly. This includes the gears, shafts, bearings, synchronizers, and other parts. Look for any signs of wear, corrosion, or damage, and replace any faulty components. Cleaning the components ensures that they function properly and reduces the risk of contaminants affecting the transmission’s performance.

| Transmission Component | Inspection and Cleaning Process |

|---|---|

| Gears | Inspect for wear and damage. Clean using a suitable degreaser. |

| Shafts | Check for bends or cracks. Clean with a wire brush and solvent. |

| Synchronizers | Ensure smooth operation. Clean and lubricate as necessary. |

Replacing worn or damaged transmission parts is crucial for a successful rebuild. This may involve installing new bearings, seals, gaskets, or synchronizers. It is important to use high-quality replacement parts from reputable manufacturers to ensure the longevity and reliability of the rebuilt transmission.

Proper assembly techniques are vital to the success of the manual transmission rebuild. Ensure that each component is positioned correctly and aligned properly. Use appropriate tools and follow the manufacturer’s specifications and torque values for tightening bolts and fasteners. Taking the time to assemble the transmission correctly will prevent future issues and ensure smooth operation.

Once the manual transmission rebuild is complete, it is essential to test and fine-tune the rebuilt transmission. This involves checking for any leaks, ensuring smooth gear shifting, and adjusting the clutch if necessary. Take the vehicle for a test drive to ensure that the rebuilt transmission functions optimally and meets the desired performance standards.

Identifying Common Signs Of Transmission Problems

When it comes to maintaining your manual transmission, it is important to be aware of the common signs that indicate potential problems. By identifying these signs early on, you can prevent further damage and costly repairs. In this blog post, we will discuss some of the most common signs of transmission problems and what they might indicate.

One of the most common signs of transmission problems is difficulty shifting gears. If you notice that it is becoming increasingly difficult to shift gears or if you experience grinding or clunking noises, it may be an indication that your transmission needs attention. This could be due to worn synchro gears or a clutch that is not working properly. It is important to have these issues addressed promptly to prevent further damage to your transmission.

Another common sign of transmission problems is leaking fluid. If you notice a pool of red or brown fluid underneath your vehicle, it is likely that there is a leak in your transmission. This could be caused by a damaged seal or gasket. It is important to address fluid leaks immediately, as low fluid levels can lead to overheating and damage to your transmission.

One more common sign of transmission problems is unusual noises. If you hear strange noises such as whining, buzzing, or clunking sounds coming from your transmission, it could indicate a problem. These noises can be caused by worn bearings, damaged gears, or a failing clutch. It is important to have your transmission inspected by a professional if you hear any unusual noises.

| Common Signs of Transmission Problems |

|---|

| Difficulty shifting gears |

| Leaking fluid |

| Unusual noises |

In conclusion, being able to identify common signs of transmission problems is crucial for maintaining the health and functionality of your manual transmission. Difficulty shifting gears, leaking fluid, and unusual noises are all indicators of potential issues. By addressing these signs promptly and seeking professional assistance if needed, you can prevent further damage and ensure the longevity of your transmission.

Step-By-Step Guide To Disassembling The Transmission

Disassembling a manual transmission is a complex but essential process in rebuilding it. This guide will provide you with a step-by-step breakdown of the disassembly process, helping you understand each crucial step along the way.

Step 1: Prepare the workspace

Before starting the disassembly process, it’s important to prepare your workspace properly. Ensure you have a clean and well-lit area to work in, with all the necessary tools and equipment readily available. It’s also a good idea to have a service manual or online guide specific to your transmission model to refer to during the disassembly.

Step 2: Drain the transmission fluid

The first step in disassembling the transmission is draining the transmission fluid. Locate the drain plug on the transmission casing and use a wrench to remove it. Make sure to have a drain pan ready to collect the fluid. Once the fluid has completely drained, reinstall the drain plug and tighten it securely.

Step 3: Remove the gearbox from the engine

To gain access to the transmission, you’ll need to remove the gearbox from the engine. Begin by disconnecting any necessary components, such as the clutch linkage and shift linkage. Using a suitable floor jack, support the weight of the gearbox while removing the mounting bolts that secure it to the engine. Lower the gearbox carefully and set it aside in a safe location.

Step 4: Disassemble the transmission casing

With the gearbox removed, you can now disassemble the transmission casing. Start by removing any external components attached to the casing, such as sensors or brackets. Then, using the appropriate tools, carefully remove all the bolts securing the casing together. Take note of the position and size of each bolt as some may vary. Once all the bolts are removed, gently separate the casing halves, revealing the internal components.

Step 5: Document and organize the internal components

Before proceeding further, it’s crucial to document and organize the internal components of the transmission. Take clear and detailed photographs, or make detailed diagrams of the arrangement and orientation of each part. This will be immensely helpful during the reassembly process.

Step 6: Remove and inspect individual transmission parts

Now that you have access to the internal components, begin removing them one by one. Carefully detach gears, shift forks, synchronizer assemblies, and any other parts attached to the transmission casing. As you remove each part, thoroughly inspect them for signs of wear, damage, or excessive play. Make a note of any parts that need to be replaced or repaired.

Step 7: Clean the transmission components

With all the parts removed, it’s time to clean them thoroughly. Use an appropriate cleaning solution and a brush to remove any accumulated dirt, grime, or old lubricant. Pay special attention to the gear teeth, synchronizer rings, and bearings, ensuring they are completely clean and free from any debris.

Step 8: Organize and store the disassembled components

After cleaning, organize and store the disassembled components in a safe and organized manner. Use separate containers or trays to keep the parts separated and prevent any damage or loss. Label each container or tray with the corresponding part name or number to maintain clarity during the reassembly process.

Conclusion

Disassembling a manual transmission is a meticulous process that requires attention to detail and careful organization. By following this step-by-step guide, you will be able to disassemble your transmission effectively and ensure a smooth rebuilding process. Remember to consult your service manual or an online guide throughout the disassembly and take note of any necessary repairs or replacements.

Inspecting And Cleaning Transmission Components

Inspecting and cleaning transmission components is a crucial step in the process of rebuilding a manual transmission. It ensures that all parts are in good condition and free from dirt, debris, and wear. By thoroughly inspecting and cleaning the transmission components, you can identify any potential problems and take appropriate measures to address them. In this blog post, we will discuss the importance of inspecting and cleaning transmission components and provide a step-by-step guide on how to do it effectively.

When rebuilding a manual transmission, it is essential to inspect each component carefully. This includes gears, synchros, bearings, shafts, and seals. The inspection process involves checking for any signs of damage, wear, or excessive play. By visually examining the components, you can identify any potential issues that may affect the transmission’s performance. It is also important to check for any dirt or debris that may have accumulated inside the transmission. This can cause friction, affect the lubrication, and lead to premature wear and tear.

Once the inspection is complete, the next step is to clean the transmission components thoroughly. Cleaning helps remove dirt, debris, and old lubricant from the parts. It is crucial to use the right cleaning agents and tools to ensure effective cleaning without causing any damage. You can use a solvent-based cleaner or specialized transmission cleaning solution to clean the components. Use a brush or a cloth to remove dirt and debris from hard-to-reach areas. It is important to be thorough and ensure that all parts are clean and free from contaminants.

- After cleaning the components, it is necessary to dry them completely before reassembling the transmission. Any moisture left on the parts can lead to corrosion and damage. You can use compressed air or a lint-free cloth to dry the components. Remember to be careful while handling the parts to avoid any scratches or damage.

- Apart from visual inspection and cleaning, it is also important to measure certain critical dimensions of the transmission components. This includes checking gear tooth wear, synchronizer ring clearance, clutch engagement clearance, and shaft endplay. By measuring these dimensions, you can ensure that the components meet the required specifications and are suitable for reuse. If any measurement is out of tolerance, it may indicate the need for replacement or further repairs.

| Component | Inspection | Cleaning | Measurements |

|---|---|---|---|

| Gears | Check for wear, damage, and play | Remove dirt and debris, dry thoroughly | Measure tooth wear |

| Synchros | Inspect for wear, damage, and proper function | Clean and lubricate, dry completely | Check synchronizer ring clearance |

| Bearings | Check for play, wear, and damage | Clean and lubricate, ensure no contaminants | Inspect for proper fit and smooth rotation |

| Seals | Inspect for leakage and wear | Clean and ensure proper sealing | N/A |

Inspecting and cleaning transmission components is a critical step in the process of rebuilding a manual transmission. It ensures that all parts are in good condition, free from contaminants, and can effectively contribute to the transmission’s overall performance. By following the steps mentioned in this blog post, you can inspect and clean the components thoroughly and ensure a successful transmission rebuild.

Replacing Worn Or Damaged Transmission Parts

Replacing worn or damaged transmission parts is a crucial step in the process of rebuilding a manual transmission. Over time, the internal components of a transmission can wear out or become damaged due to various factors such as normal wear and tear, improper maintenance, or even an accident. In this blog post, we will discuss the importance of replacing these worn or damaged parts and provide you with a step-by-step guide on how to do it effectively.

When a transmission component becomes worn or damaged, it can negatively impact the overall performance and durability of the transmission. Some common signs of worn or damaged parts include grinding noises, difficulty shifting gears, slipping, or leaking fluids. Ignoring these signs can lead to further damage to the transmission and even complete failure. Therefore, it is crucial to address these issues promptly and replace the worn or damaged parts to ensure the longevity and proper functioning of your transmission.

Before diving into the process of replacing the transmission parts, it is important to have a clear understanding of the specific parts that may need replacement. These can vary depending on the make and model of your vehicle, as well as the specific issue you are experiencing. Some common transmission parts that may require replacement include clutch discs, pressure plates, bearings, synchronizers, gears, and seals. It is essential to identify the exact parts that need replacement to avoid unnecessary costs and ensure the proper functioning of the rebuilt transmission.

Proper Assembly Techniques For Rebuilding The Transmission

When it comes to rebuilding a manual transmission, proper assembly techniques are crucial to ensure that the transmission functions optimally. A well-assembled transmission will provide smooth shifting and reliable performance. In this blog post, we will discuss the key steps and techniques involved in properly assembling a rebuilt manual transmission.

Before beginning the assembly process, it is important to have all the necessary tools and equipment at hand. This includes a transmission assembly bench, a torque wrench, a bearing puller, snap ring pliers, and various other specialized tools. Additionally, it is essential to have the manufacturer’s service manual or rebuild instructions readily available, as they provide important specifications and guidelines for the assembly process.

The first step in the assembly process is to thoroughly clean all the transmission components. This includes the gears, synchronizers, bearings, shafts, and other parts. Cleaning the components helps to remove any dirt, debris, or old lubricant that may be present, ensuring smooth operation and longevity of the rebuilt transmission. It is recommended to use a parts cleaning solvent and a stiff brush to clean the components thoroughly.

- Inspecting the components: After cleaning, it is crucial to carefully inspect all the components for any signs of wear, damage, or deformation. This includes checking the gear teeth for excessive wear, inspecting the synchronizers for wear or damage, and verifying the condition of bearings and shafts. Any worn or damaged components should be replaced with new ones to ensure the transmission’s reliability and performance.

- Assembling the gears and shafts: Once the components are cleaned and inspected, the next step is to assemble the gears and shafts. This involves carefully aligning the gears on the shafts and securing them with the appropriate bearings and snap rings. It is important to follow the manufacturer’s specifications for gear lash, bearing preload, and snap ring installation torque to ensure proper functioning.

- Installing the synchronizers: The synchronizers play a crucial role in enabling smooth shifting between gears. During the assembly process, it is important to install the synchronizers correctly, ensuring proper engagement with the gears. Additionally, the synchronizer springs and keys should be installed according to the manufacturer’s specifications to ensure optimal shifting performance.

Once all the components are assembled, it is important to perform a thorough final inspection to verify that everything is in order. This includes checking the gear engagement, synchronizer operation, and the smooth rotation of the shafts. If any issues are identified during the final inspection, they should be addressed and rectified before proceeding.

| Step | Action |

|---|---|

| 1 | Clean all transmission components |

| 2 | Inspect components for wear or damage |

| 3 | Assemble gears and shafts according to specifications |

| 4 | Install synchronizers and associated parts |

| 5 | Perform final inspection |

Proper assembly techniques are essential for the successful rebuilding of a manual transmission. By following the manufacturer’s specifications, thoroughly cleaning and inspecting the components, and carefully assembling each part, one can ensure a reliable and high-performing transmission. Remember, attention to detail and adherence to the proper assembly techniques will result in a transmission that provides smooth shifting and optimal performance.

Testing And Fine-Tuning The Rebuilt Manual Transmission

Testing And Fine-Tuning The Rebuilt Manual Transmission

After successfully rebuilding a manual transmission, it is important to properly test and fine-tune it to ensure optimal performance. This step is crucial in making sure that the transmission functions smoothly and efficiently. A thorough testing process allows for the identification of any issues or problems that may have been missed during the rebuilding process. Fine-tuning, on the other hand, involves making minor adjustments to various components to further enhance the transmission’s performance.

One of the initial steps in testing the rebuilt manual transmission is to perform a visual inspection of all the components. This includes examining the gears, shafts, bearings, and synchronizers for any signs of wear, damage, or misalignment. Any faulty or worn-out components should be replaced to avoid potential issues in the future. It is important to ensure that all the parts are clean and functioning properly before proceeding with the testing phase.

Once the visual inspection has been completed, the next step is to carry out a series of performance tests on the transmission. This involves operating the transmission in different gears and at various speeds to evaluate its overall functionality. Paying close attention to any unusual noises, vibrations, or difficulties in shifting gears is crucial during these tests. A thorough assessment of the transmission’s performance will help identify any underlying problems that need to be addressed before the final fine-tuning stage.

Now comes the crucial process of fine-tuning the rebuilt manual transmission. This involves making minor adjustments to various components to ensure optimal performance. One important aspect of fine-tuning is to properly adjust the shift linkage. The shift linkage determines how smoothly and accurately the gears are engaged. Adjusting the shift linkage can help eliminate any issues with grinding, slipping, or difficulty in shifting gears. Additionally, the clutch system should be adjusted to ensure proper engagement and disengagement.

Using a dynamometer can greatly assist in fine-tuning the rebuilt manual transmission. A dynamometer provides a controlled environment where the transmission’s performance can be accurately measured and analyzed. It allows for precise adjustments to be made, such as optimizing gear ratios and clutch settings. Additionally, a dynamometer can assess the transmission’s power output and torque, ensuring that it meets the desired specifications.

In conclusion, testing and fine-tuning the rebuilt manual transmission is a crucial step in ensuring its optimal performance. By conducting thorough performance tests, visually inspecting the components, and making necessary adjustments, any potential issues can be identified and resolved. Properly fine-tuning the transmission will result in smoother gear shifts, enhanced overall performance, and increased longevity.

Frequently Asked Questions

1. Why should I consider a manual transmission rebuild?

A manual transmission rebuild is necessary when your transmission is experiencing significant problems such as grinding gears, difficulty shifting, or slipping out of gear. Rebuilding allows you to replace worn or damaged components and restore the transmission’s performance and durability.

2. What are some common signs of transmission problems in a manual car?

Common signs of transmission problems in a manual car include difficulty shifting gears, noisy transmission operation, clutch slippage, unusual smells or burning odor, and leaking transmission fluid. If you notice any of these signs, it’s best to have your transmission inspected and repaired.

3. How do I disassemble a manual transmission step-by-step?

To disassemble a manual transmission, start by draining the fluid, removing the driveshafts, disconnecting the clutch, and detaching the transmission from the engine. Then, carefully disassemble the transmission housing, gears, and other internal components, following the manufacturer’s guidelines or a repair manual.

4. What should I inspect and clean in a manual transmission rebuild?

During a manual transmission rebuild, it is important to thoroughly inspect and clean various components such as gears, synchronizers, bearings, shafts, and seals. Look for signs of wear, damage, or excessive build-up, and clean everything using appropriate solvents or cleaners.

5. How do I identify and replace worn or damaged transmission parts?

To identify worn or damaged transmission parts, visually inspect each component for signs of wear, cracks, or other noticeable damage. Test the functionality and measure tolerances of crucial parts, such as bearings or synchronizers, using appropriate tools. Replace any damaged or excessively worn parts to ensure a proper rebuild.

6. What are some recommended assembly techniques for rebuilding a manual transmission?

When assembling a rebuilt manual transmission, make sure to follow the manufacturer’s instructions or a repair manual. Use the appropriate tools and torque specifications for tightening fasteners. Properly lubricate components with the recommended transmission fluid or grease. Take your time and ensure precise assembly to avoid future issues.

7. How do I test and fine-tune a rebuilt manual transmission?

After rebuilding a manual transmission, it is crucial to test its functionality and ensure proper performance. Test the transmission’s shifting and gear engagement in a safe and controlled environment. Fine-tune any adjustments if necessary, such as clutch pedal engagement or shift linkage adjustments, to achieve optimal operation.