Welcome to our blog post where we delve into the world of CVT transmissions. In this article, we will provide you with an overview of CVT transmissions, exploring their common issues and failures.

We will also take a closer look at the feasibility of rebuilding these transmissions, discussing the process involved, the tools and equipment required, as well as the challenges and considerations to keep in mind. Lastly, we will weigh the benefits and drawbacks of rebuilding CVT transmissions, providing you with valuable insights to help you make an informed decision. So, let’s get started and dive into this comprehensive guide on CVT transmission rebuilding.

Overview Of Cvt Transmissions

CVT transmissions, or continuously variable transmissions, are a type of automatic transmission that offers seamless acceleration and a smooth driving experience. Unlike traditional transmissions with a set number of gears, CVT transmissions can change seamlessly through an infinite number of gear ratios, providing optimal performance and fuel efficiency. This technology has gained popularity in recent years and is now commonly found in many vehicles.

One of the key advantages of CVT transmissions is their ability to optimize engine performance by keeping the engine operating at its most efficient speed. This can result in improved fuel economy compared to traditional transmissions. Additionally, CVT transmissions provide a smoother and more comfortable driving experience, as there are no noticeable shifts between gears.

However, like any technology, CVT transmissions also have their limitations and potential issues. One common concern with CVT transmissions is their durability and long-term reliability. Some drivers have reported issues with CVT transmissions failing prematurely or requiring expensive repairs. It is important to note that not all CVT transmissions experience problems, but it is crucial for drivers to be aware of the potential risks.

- On the topic of rebuilding CVT transmissions, it is important to understand whether this process is feasible. Rebuilding a CVT transmission involves disassembling and inspecting various components, replacing any worn or damaged parts, and reassembling the transmission to its original specifications.

- Whether a CVT transmission can be successfully rebuilt depends on several factors. The availability of replacement parts and the expertise of the technician performing the rebuild are crucial. As CVT transmissions are relatively complex systems, specialized tools and equipment may also be required. It is essential to consult with a professional before attempting to rebuild a CVT transmission to ensure the process is feasible and to avoid further damage.

- Rebuilding a CVT transmission can be a challenging task due to its intricate design and complexity. Additionally, the process may require specific training and expertise. It is important to consider these challenges and potential limitations before deciding to rebuild a CVT transmission. Consulting a professional transmission specialist or mechanic experienced in CVT transmissions is highly recommended in order to ensure a successful rebuild and avoid costly mistakes.

| Benefits of Rebuilding CVT Transmissions | Drawbacks of Rebuilding CVT Transmissions |

|---|---|

| 1. Cost savings compared to purchasing a new transmission. | 1. Possibility of encountering further issues or complications during the rebuild process. |

| 2. Potential for improved transmission performance and reliability after the rebuild. | 2. Limited availability of replacement parts for certain CVT transmission models. |

| 3. Retaining the original transmission rather than replacing it with a different type of transmission. | 3. Rebuilding a CVT transmission may not be a long-term solution, depending on the condition of the transmission and its components. |

Common Issues And Failures In Cvt Transmissions

CVT (Continuously Variable Transmission) systems have become increasingly popular in modern vehicles due to their smooth and efficient performance. However, like any other mechanical system, CVT transmissions are prone to certain issues and failures that can impact their overall functionality and lifespan. One common issue that arises in CVT transmissions is overheating, which can be caused by several factors such as low fluid levels, excessive loads, or a malfunctioning cooling system. Overheating can lead to accelerated wear and tear on the transmission components, ultimately resulting in transmission failure.

Another issue commonly encountered in CVT transmissions is belt or chain slipping. The belt or chain in a CVT transmission is responsible for transmitting power from the engine to the wheels. When the belt or chain slips, it causes a loss of power and a decrease in overall vehicle performance. This slipping can occur due to inadequate tensioning of the belt or chain, excessive wear, or the presence of foreign debris.

Furthermore, CVT transmissions are also susceptible to valve body failures. The valve body is a crucial component that regulates the flow of transmission fluid and controls gear shifting in CVT systems. Any malfunction or damage to the valve body can result in erratic shifting, loss of power, or complete transmission failure. Additionally, issues with the solenoid valves, which control the hydraulic pressure within the transmission, can also lead to problematic shifting and transmission issues.

- Fluid leaks:

- Delayed engagement:

- Strange noises:

| Issue | Possible Cause |

|---|---|

| Overheating | Low fluid levels, excessive loads, malfunctioning cooling system |

| Belt or Chain Slipping | Inadequate tensioning, excessive wear, presence of foreign debris |

| Valve Body Failures | Malfunction or damage of the valve body, issues with solenoid valves |

Understanding The Feasibility Of Rebuilding Cvt Transmissions

CVT (Continuously Variable Transmission) is a type of automatic transmission that provides seamless acceleration and higher fuel efficiency compared to conventional transmissions. However, like any mechanical system, CVT transmissions may encounter issues and failures over time. In such cases, the question arises, “Can you rebuild CVT transmissions?”

Rebuilding a CVT transmission involves dismantling and repairing the faulty components, rather than replacing the entire transmission unit. This process requires specialized knowledge, skills, and tools. The feasibility of rebuilding a CVT transmission depends on various factors, including the severity of the failure, availability of spare parts, and the expertise of the technician.

One of the primary considerations for successfully rebuilding a CVT transmission is the availability of spare parts. Unlike traditional transmissions, which have been around for decades and have a wide range of compatible parts available, CVT transmissions are relatively new, and finding specific parts can be challenging. However, as the popularity of CVT transmissions increases, the availability of spare parts is also expected to improve.

Additionally, the expertise of the technician plays a crucial role in determining the feasibility of rebuilding a CVT transmission. Unlike manual or conventional automatic transmissions, CVT transmissions require specific knowledge and skills to diagnose and repair. Rebuilding a CVT transmission requires an in-depth understanding of the complex mechanisms and electronic components involved.

- Availability of spare parts

- Expertise of the technician

| Pros of Rebuilding CVT Transmissions | Cons of Rebuilding CVT Transmissions |

|---|---|

| 1. Cost-effective compared to a full transmission replacement. | 1. Limited availability of spare parts. |

| 2. Preserves the original transmission unit. | 2. Requires specialized knowledge and skills. |

| 3. Can potentially extend the lifespan of the transmission. | 3. May not offer the same level of reliability as a new transmission. |

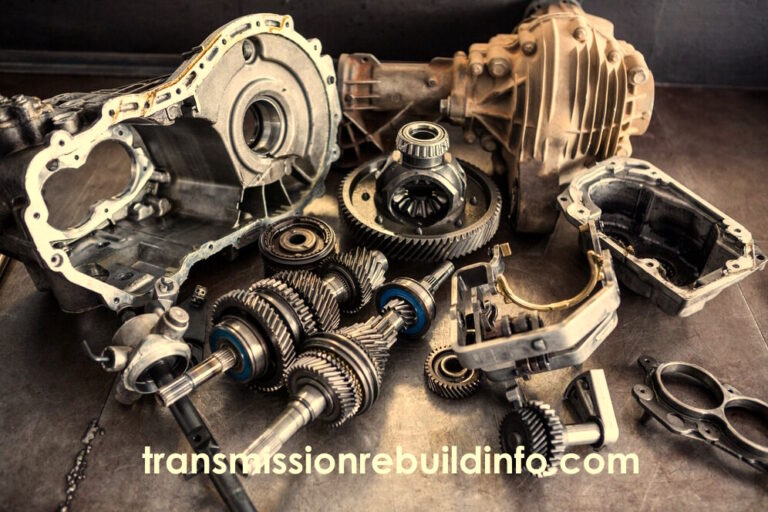

The Process Of Rebuilding Cvt Transmissions

A continuously variable transmission (CVT) is a type of transmission that provides seamless shifting and infinite gear ratios. Over time, CVT transmissions may require rebuilding due to wear and tear or the presence of mechanical issues. Rebuilding a CVT transmission involves disassembling the unit, inspecting and replacing worn or damaged parts, and then reassembling it to restore its functionality and performance.

The process of rebuilding a CVT transmission begins with the removal of the transmission from the vehicle. This typically involves disconnecting the drivetrain components and fluid lines. Once the transmission is removed, it is disassembled into its various components, such as the pulleys, belts, and hydraulic systems.

The next step is to inspect each component for signs of damage or wear. This may involve measuring clearances, checking for fluid leaks, and identifying any faulty or worn-out parts. Components that are found to be damaged or worn beyond acceptable limits need to be replaced.

- Can you rebuild a CVT transmission?

The answer to this question is yes, but it requires extensive knowledge, experience, and specialized tools. Rebuilding a CVT transmission is a complex task that should be performed by trained professionals or experienced mechanics. It involves a deep understanding of the transmission’s internal workings, intricate adjustments, and precise reassembly.

The process of rebuilding a CVT transmission also includes the use of specific tools and equipment. These may include torque wrenches, transmission jacks, bearing pullers, and other specialized tools to properly disassemble and reassemble the transmission. Additionally, it may require access to manufacturer-specific diagnostic software to calibrate and program the rebuilt transmission for optimal performance.

| Basic Steps in Rebuilding a CVT Transmission |

|---|

| 1. Removal of the transmission from the vehicle. |

| 2. Disassembling the transmission into its various components. |

| 3. Inspecting each component for signs of damage or wear. |

| 4. Replacing damaged or worn-out parts. |

| 5. Properly reassembling the transmission. |

| 6. Testing and calibrating the rebuilt transmission. |

Finally, after the transmission has been rebuilt and reinstalled in the vehicle, it needs to be thoroughly tested for functionality and performance. This testing may involve checking for smooth shifting, proper engagement of gears, and verifying that the transmission operates within acceptable temperature and pressure ranges.

In conclusion, the process of rebuilding a CVT transmission is a complex and intricate task that requires specialized knowledge, experience, and tools. While it is possible to rebuild a CVT transmission, it is recommended to seek the assistance of professionals or experienced mechanics to ensure a successful and reliable rebuilding process.

Tools And Equipment Required For Cvt Transmission Rebuilding

When it comes to rebuilding a CVT (Continuously Variable Transmission), having the right tools and equipment is essential. The complexity of CVT transmissions requires specialized tools to ensure a proper rebuild. One of the most important tools needed is a CVT transmission fixture. This fixture is used to securely hold the transmission during the rebuilding process, allowing for easy access to all the components. Without this fixture, the process would be much more difficult and time-consuming.

In addition to the fixture, a set of CVT transmission tools is also necessary. These tools include various wrenches and sockets specifically designed for CVT transmissions, as well as a torque converter holding tool. The torque converter holding tool is used to prevent the converter from turning while removing or installing the transmission bolts. This tool is crucial in order to properly torque the bolts and ensure a tight and secure connection.

Another important piece of equipment required for CVT transmission rebuilding is a transmission jack. This specialized jack is designed to safely support and lower the transmission during the removal and installation process. It has adjustable arms and a sturdy base to provide stability and prevent any damage to the transmission or surrounding components.

- In addition to these tools and equipment, it is also essential to have a clean and organized workspace. A clean environment is crucial when working on sensitive and intricate parts of a CVT transmission. Dust, dirt, and debris can easily cause damage to the components, leading to potential issues and failures in the future.

| Common CVT Transmission Tools | Common CVT Transmission Equipment |

|---|---|

|

|

Challenges And Considerations In Rebuilding Cvt Transmissions

When it comes to rebuilding CVT (Continuously Variable Transmission) transmissions, there are several challenges and considerations that need to be taken into account. CVT transmissions have gained popularity in recent years due to their smoother shifting and improved fuel efficiency compared to traditional automatic transmissions. However, their complex design poses unique challenges for mechanics and technicians when it comes to rebuilding them. In this blog post, we will explore some of the challenges involved in rebuilding CVT transmissions and discuss the considerations that need to be kept in mind.

One of the main challenges in rebuilding CVT transmissions is the intricate and complex nature of their design. Unlike traditional automatic transmissions, which use a fixed number of gears, CVT transmissions use a system of pulleys and belts to provide an infinite number of gear ratios. This means that each component of the CVT transmission needs to be carefully inspected and evaluated for wear and tear. Additionally, the high number of moving parts in a CVT transmission can make the rebuilding process more time-consuming and labor-intensive.

Another challenge in rebuilding CVT transmissions is the availability of parts. Due to the relative newness of CVT transmissions, finding suitable replacement parts can be challenging. CVT transmissions have evolved rapidly over the past decade, with various manufacturers developing their own unique designs and technologies. As a result, finding compatible parts for a specific CVT transmission model can be difficult, especially for older or less common vehicles. Mechanics and technicians may need to rely on specialized suppliers or salvage yards to source the necessary parts.

- One consideration that needs to be kept in mind when rebuilding CVT transmissions is the level of expertise and knowledge required. CVT transmissions are highly specialized systems, and not all mechanics and technicians are familiar with their intricacies. Rebuilding a CVT transmission requires a deep understanding of the internal components and their interaction with each other. Mechanics and technicians may need to invest time and effort in learning about CVT transmissions and staying updated with the latest advancements in their design and technology.

- An additional consideration is the cost-effectiveness of rebuilding a CVT transmission. While rebuilding can be a more affordable option compared to purchasing a brand new transmission, it may not always be the most cost-effective solution. Depending on the extent of the damage or wear, rebuilding a CVT transmission may only provide a temporary fix. If the transmission is highly damaged or nearing the end of its lifespan, it may be more prudent to replace it altogether.

| Benefits of Rebuilding CVT Transmissions | Drawbacks of Rebuilding CVT Transmissions |

|---|---|

|

|

Benefits And Drawbacks Of Rebuilding Cvt Transmissions

A continuously variable transmission (CVT) is a type of automatic transmission that can change seamlessly through a continuous range of gear ratios. Unlike traditional transmissions, which use fixed gears, CVTs use a belt or chain mechanism to provide an infinite number of gear ratios. This allows for better fuel efficiency and smoother acceleration. However, CVTs can sometimes experience issues and failures that require rebuilding.

Benefits of rebuilding CVT transmissions:

- Cost-effectiveness: Rebuilding a CVT transmission can be a more affordable option compared to purchasing a brand new transmission. This is especially true if the vehicle’s overall condition is still good and only the transmission needs attention.

- Extended lifespan: By rebuilding a CVT transmission, its lifespan can be significantly extended. This means the vehicle can continue to operate efficiently for a longer period of time without the need for a complete transmission replacement.

- Improved performance: Rebuilding a CVT transmission can help restore its performance to its original or even better state. This can result in smoother shifting, reduced vibration, and increased overall driving comfort.

Drawbacks of rebuilding CVT transmissions:

| 1. Complexity | Rebuilding a CVT transmission is a complex process that requires specialized knowledge and tools. It is not a simple DIY project and should be done by experienced professionals. |

|---|---|

| 2. Limited lifespan after rebuilding | While a rebuilt CVT transmission can offer extended lifespan, it may not match the longevity of a new transmission. The rebuilt transmission may still be prone to wear and tear over time. |

| 3. Potential for recurring issues | Even after rebuilding, there is a possibility that the CVT transmission may encounter similar issues in the future. This can lead to additional costs and potential downtime for the vehicle. |

In conclusion, rebuilding a CVT transmission can have its benefits, such as cost-effectiveness, extended lifespan, and improved performance. However, it is important to consider the drawbacks, including the complexity of the process, limited lifespan compared to a new transmission, and the potential for recurring issues. It is recommended to consult with a professional technician to assess the feasibility of rebuilding a CVT transmission and to ensure it is the best course of action for your specific vehicle.

Frequently Asked Questions

What are some common issues and failures in CVT transmissions?

Some common issues and failures in CVT transmissions include belt slippage, overheating, fluid contamination, and valve body problems.

Is it feasible to rebuild CVT transmissions?

Yes, it is possible to rebuild CVT transmissions. However, it requires specialized knowledge, experience, and access to the necessary tools and equipment.

What is the process of rebuilding CVT transmissions?

The process of rebuilding CVT transmissions typically involves disassembling the transmission, inspecting and replacing worn or damaged components, cleaning and reassembling the transmission, and then testing it to ensure proper functionality.

What tools and equipment are required for CVT transmission rebuilding?

Some of the tools and equipment required for CVT transmission rebuilding include torque wrenches, transmission rebuilding kits, transmission jacks, diagnostic scanners, and various hand tools.

What are the challenges and considerations in rebuilding CVT transmissions?

Some of the challenges and considerations in rebuilding CVT transmissions include the complexity of the transmission, the availability of parts, the need for specialized training, and the potential for additional damage or issues during the rebuilding process.

What are the benefits of rebuilding CVT transmissions?

The benefits of rebuilding CVT transmissions include cost savings compared to purchasing a new transmission, the ability to restore the functionality of a vehicle, and the potential for improved performance and longevity.

What are the drawbacks of rebuilding CVT transmissions?

Some drawbacks of rebuilding CVT transmissions include the time and effort required for the rebuilding process, the potential for additional issues or failures in the future, and the need for expertise in CVT transmissions.